Evaluating the Thermal Insulation Properties of Fabric Acoustic Panels

Thermal and Acoustic Synergy in Fabric Panels

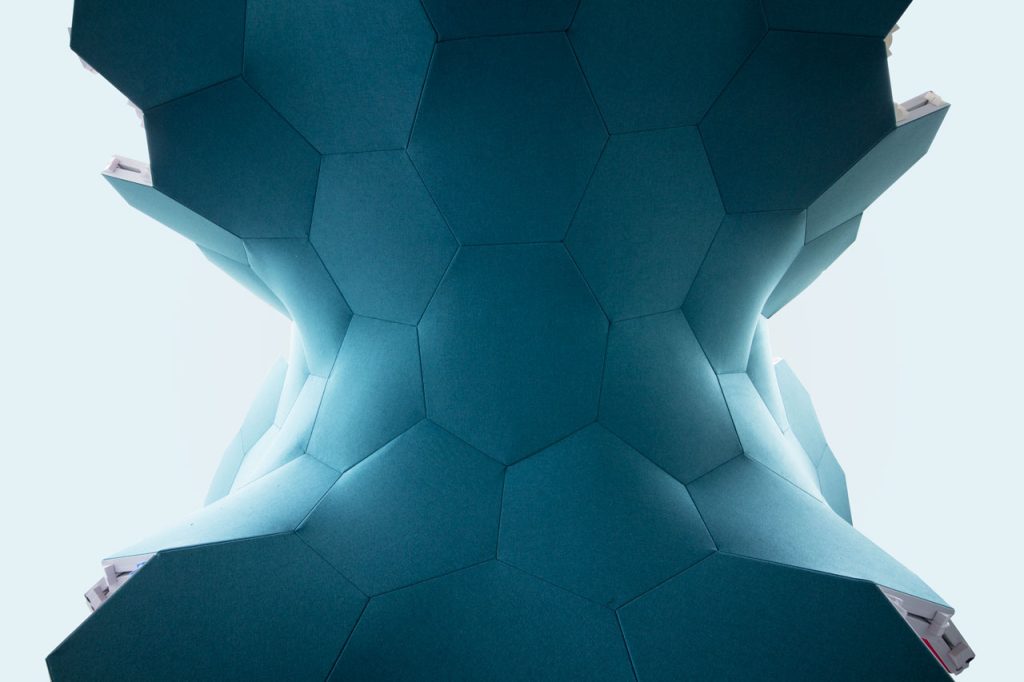

Fabric acoustic panels are primarily known for their sound absorption capabilities, but their role in thermal insulation is increasingly gaining attention. Understanding the thermal properties of these panels is crucial for optimising indoor environments, particularly in terms of energy efficiency and comfort. This article examines the thermal insulation properties of fabric acoustic panels and their implications for building design.

Thermal Insulation Mechanisms

Material Composition

The thermal insulation properties of fabric acoustic panels are largely determined by the materials used in their construction. High-density materials like fibreglass and mineral wool, commonly used in the core of these panels, possess excellent thermal insulation properties. These materials trap air within their fibres, reducing heat transfer and thereby enhancing insulation². The outer fabric layer, typically made from polyester or wool, also contributes to the panel’s overall thermal performance by adding an additional barrier to heat flow³.

Panel Thickness

The thickness of the acoustic panel plays a significant role in its thermal insulation capabilities. Thicker panels provide more substantial barriers to heat transfer, improving the overall thermal resistance of the panel. This increased thickness allows for greater air trapping and reduced thermal conductivity, which is essential for maintaining comfortable indoor temperatures⁴.

Impact of Fabric Density on Thermal Properties

High-Density Fabrics

High-density fabrics, such as tightly woven wool or polyester, enhance the thermal insulation properties of acoustic panels. These fabrics reduce the movement of air through the panel, minimising convective heat transfer. As a result, high-density fabrics contribute significantly to the panel’s ability to retain heat during colder months and keep interiors cool during warmer periods⁵.

Low-Density Fabrics

While low-density fabrics like loosely woven cotton or linen offer less thermal resistance compared to their high-density counterparts, they can still contribute to the overall insulation when used in combination with high-performance core materials. The breathability of low-density fabrics can help manage moisture levels, which indirectly affects thermal comfort by preventing the buildup of humidity within the panel⁶.

Applications in Building Design

Energy Efficiency

Integrating fabric acoustic panels with strong thermal insulation properties into building designs can lead to significant energy savings. These panels help maintain stable indoor temperatures, reducing the reliance on heating and cooling systems. In turn, this lowers energy consumption and contributes to a building’s overall sustainability⁷. The dual function of acoustic and thermal management makes these panels a valuable addition to energy-efficient building projects.

Comfort and Well-being

Thermal comfort is a critical aspect of occupant well-being in both residential and commercial buildings. Fabric acoustic panels that provide effective thermal insulation can enhance indoor comfort by maintaining consistent temperatures and reducing drafts. This improved thermal environment contributes to the overall comfort and productivity of building occupants⁸.

Future Directions in Thermal Acoustic Panels

Advanced Materials

The development of advanced materials, such as aerogels and phase change materials (PCMs), holds promise for enhancing the thermal insulation properties of fabric acoustic panels. Aerogels, with their low thermal conductivity, can significantly boost insulation without adding substantial weight or thickness. PCMs, which absorb and release thermal energy during phase transitions, can help regulate indoor temperatures by storing and releasing heat as needed⁹.

Sustainable Practices

Sustainability is a key consideration in modern building design. Using eco-friendly materials in fabric acoustic panels not only improves their thermal and acoustic performance but also reduces environmental impact. Recycled fibres and natural materials like wool and hemp are increasingly being used to create sustainable acoustic panels with excellent thermal properties¹⁰.

References

- Arau-Puchades, H. (1999). Acoustics and absorbers: Porous materials. Journal of Sound and Vibration, 220(4), 925-938.

- Bies, D. A., & Hansen, C. H. (2009). Engineering noise control: Theory and practice. CRC Press.

- Woolmark. (2020). Wool and flame resistance.

- Fahy, F. J. (2000). Foundations of engineering acoustics. Academic Press.

- Cox, T. J., & D’Antonio, P. (2009). Acoustic absorbers and diffusers: Theory, design and application. CRC Press.

- Trevira CS. (2021). Trevira CS: Permanently flame retardant textiles.

- Blauert, J., & Xiang, N. (2008). Acoustics for engineers. Springer.

- Malucelli, G., et al. (2014). Nano-coatings for flame retardancy of textiles. Progress in Organic Coatings, 77(6), 1074-1091.

- Sriram, R., et al. (2018). Smart textiles for fire safety. Sensors and Actuators B: Chemical, 259, 1198-1204.

- GREENGUARD. (2020). Low VOC emissions.

Share